MH Couplings

Coupling is a device that connects two shafts or shafts and rotating parts, rotates together in the process of transmitting motion and power, and does not separate under normal conditions.

About Coupling

The coupling is composed of two parts, which are respectively connected with the driving shaft and the driven shaft. Generally, the power machine is connected with the working machine by means of coupling.

Coupling is a device condition that connects two shafts or two shafts and rotating parts, rotates together in the process of transmitting motion and power, and does not separate under normal conditions. Sometimes it can also be used as a safety device to prevent the connection part from bearing excessive load and play the role of overload protection.

Some couplings

Flexible Coupling

The flexible coupling is a kind of coupling which allows the rotor to have a separate axial displacement, and there is a certain deviation between the two rotors.

Flexible coupling refers to the ability to compensate the relative offset of the axes of the two connected shafts.

It is used to connect two shafts (driving shaft and driven shaft) in different mechanisms to make them rotate together to transfer torque.

Plum Coupling

Plum blossom coupling is a kind of widely used coupling, also known as claw coupling, which is composed of two metal claw discs and an elastomer. The two metal claw plates are generally 45 steel, but aluminum alloy is also used when the load sensitivity is required.

It can’t deal with large deviation, especially axial deviation.

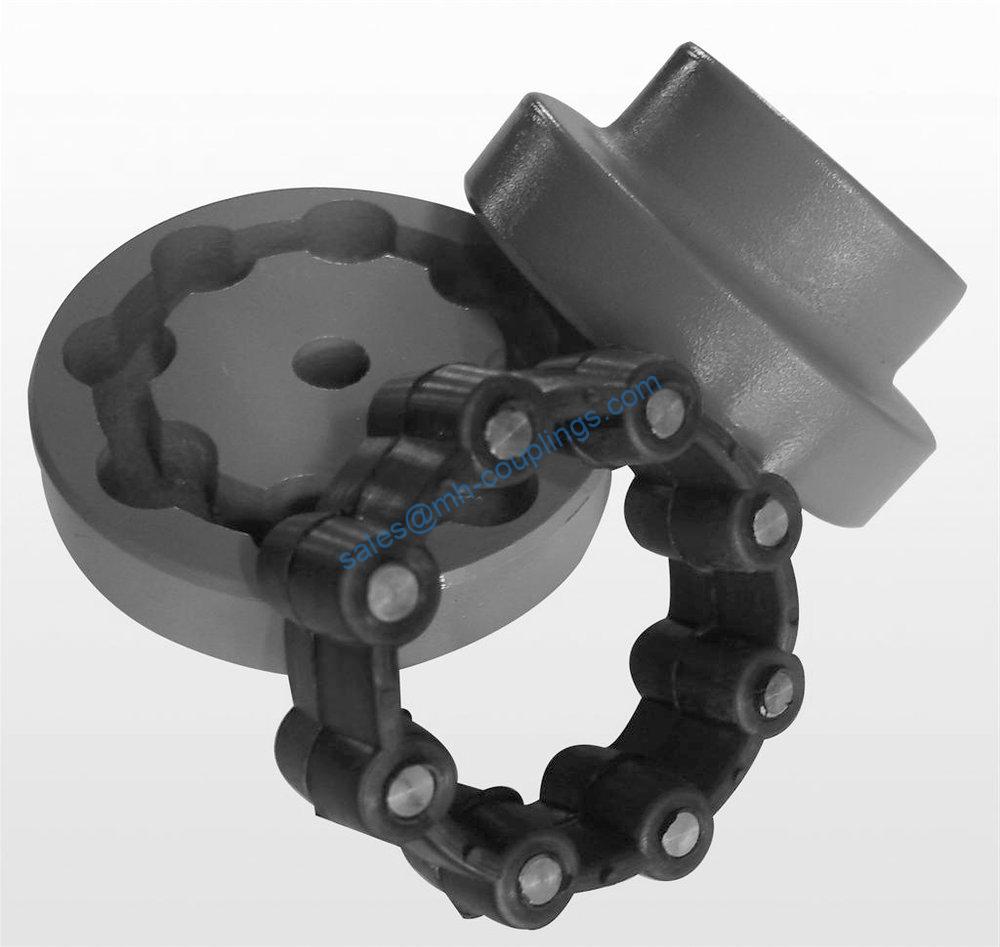

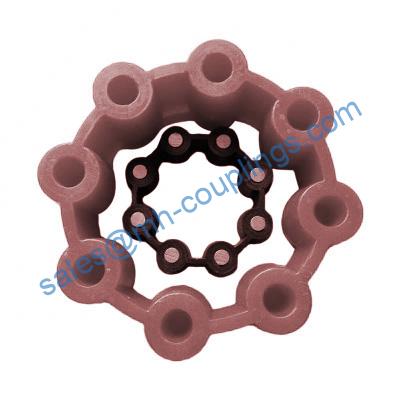

MH Coupling

MH core type coupling is made of selected cast iron, which has the advantages of compression and tensile strength, high hardness, good toughness, bearing large load, and embedded rigid pipe core, with good transmission performance and shock absorption performance, which can make the overall operation stable and more durable.

Products

In high-speed and heavy-duty power transmission, some couplings have the functions of buffering, damping and improving the dynamic performance of shafting.

Pric F Flexible Coupling

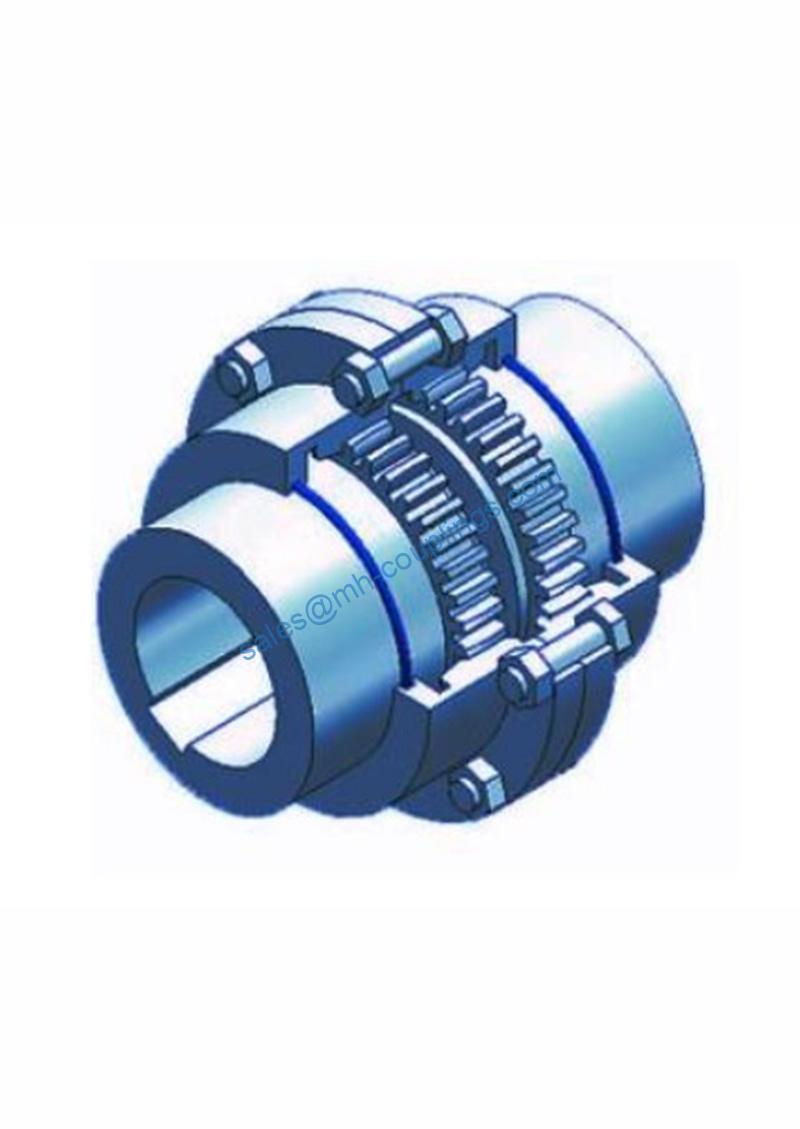

Gear Coupling

Gear coupling

Common couplings

Most of the commonly used couplings have been standardized or standardized. Generally, it is only necessary to correctly select the type of coupling, determine the model and size of coupling. If necessary, check and calculate the load capacity of the vulnerable weak links; when the speed is high, check and calculate the centrifugal force of the outer edge and the deformation of the elastic element, and check the balance.

What is coupling

Coupling can be divided into rigid coupling and flexible coupling. It is used to connect the driving shaft and driven shaft in different mechanisms firmly, rotate together, and transmit motion and torque.

MH Coupling

Flexible

Flex coupling

Standard

Mh Coupling

Mh PU Coupling

Rubber Mh Couplings

Elastomeric Coupling

MH series hysteresis coupling

MH series hysteresis coupling is mainly composed of permanent disk, induction disk, induction disk, cylinder, cover, sleeve, adjusting nut, etc. The core part is mainly composed of a permanent magnetic disk and an induction disk, which are arranged relative to each other and adjusted with a certain gap. Several pieces of magnetic steel with alternating polarity are distributed on the permanent magnetic disk, so a complex magnetic field with alternating polarity is formed on the induction disk. When there is relative rotation between the permanent magnetic disk and the induction disk, the change of the magnetic field of the induction disk always lags behind the change of the magnetic field of the permanent magnetic disk, thus a hysteresis moment is generated to prevent the relative rotation between them, that is to say, the “magnetic connection” is realized. When the hysteresis moment is not enough to prevent the relative rotation between them, there is a slip between the permanent magnetic disk and the induction disk. The torque transmitted by the hysteresis coupling is the hysteresis torque between the permanent disk and the induction disk. When the disk gap is fixed, the torque is constant. Therefore, the hysteresis coupling has the characteristics of constant output torque and slipping when overload. By adjusting the gap between the permanent disk and the induction disk of the hysteresis coupling, the transmission torque of the hysteresis coupling can be changed in a certain range.